Building Safety Month

/A three-part series exploring engineering and environmental issues supporting Building Safety. Topics include Electrical Safety, Poor Ventilation: Impact and Solutions, and Crane Structural Safety.

Building Safety

Safety in building construction traces to the Code of Hammurabi around 1750 BC, offering rather straightforward dis-incentives of re-work or death. A mere six rules pertained to damages due a builder for his failure to properly construct a home. Building and natural catastrophes like the Great Fire of London (1666), the Great Fire of Chicago (1871), 1906 San Francisco Earthquake, and more recent Hurricane Sandy led to voluminous developments to identify risks, create consistent standards, and changes to reflect new materials and methods.

The International Code Council’s (ICC) 2015 International Building Code contains slightly less than 700 pages; 35 chapters and 13 appendices, with the singular focus of providing a model for minimum acceptable safety standards to protect public health and welfare for every type of building occupancy. Modern codes go one step further and also provided minimum standards for sustainability related to energy consumption. And the IBC is just one of many standards and guidelines we work with in industrial, commercial, municipal projects.

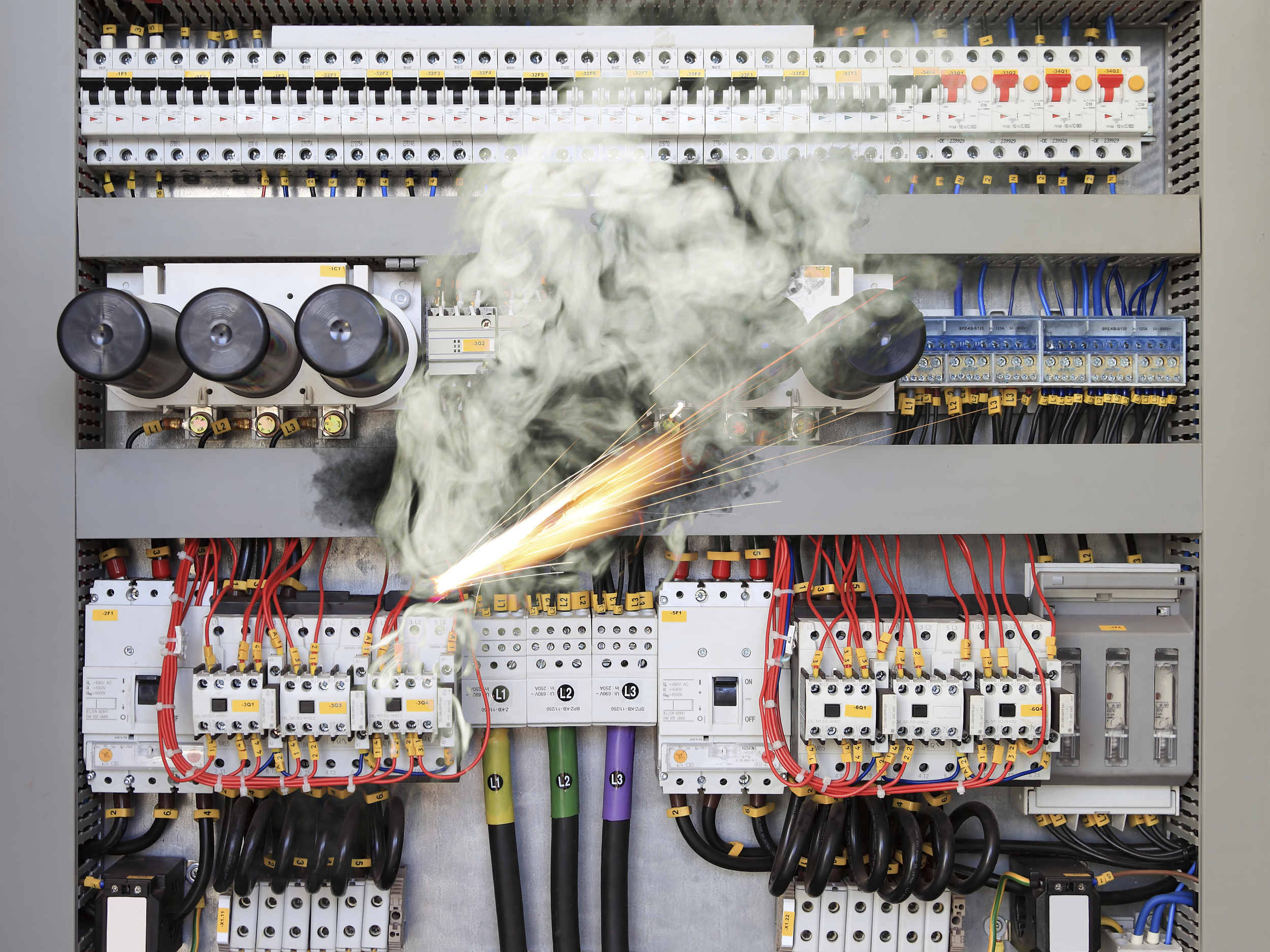

Part 1: Electrical Safety

Opportunities for electrical faults and associated health risks to workers exist throughout industrial, municipal, and institutional facilities, with electrical distribution equipment and large equipment associated with manufacturing, process systems, research, HVAC, and central utility plants. The IBC by reference to the NEC (National Electrical Code) and NFPA (National Fire Protection Association) dictates that an electrical system be evaluated for Arc Flash hazards and that equipment be appropriately labeled according to the protection required. Hazards associated with electricity is a serious workplace hazard; The Electric Power Research Institute (EPRI http://www.epri.com/Pages/Default.aspx ) and National Institute for Occupational Safety and Health (NIOSH http://www.cdc.gov/niosh/) have very good videos (https://www.youtube.com/watch?v=fZP47mlELSc and https://www.youtube.com/watch?v=-RkbMdaeq0o ) describing research into arc flash and stories by those affected by incidents.

Consider your building. Have you completed an ArcFlash Hazard Analysis for the facility? Do you have a defined electrical safety program and proper training and PPE for your employees? Does your electrical equipment have warning labels that comply with NFPA 70E, OSHA, or ANSI Z 535?

We can help. SSM supports numerous clients by performing comprehensive electrical distribution and equipment assessments; conducting short circuit analysis, time current coordination studies and identifying Hazards.

FOR MORE INFORMATION: Emerick Martin, PE, Senior Electrical Engineer

Part 2: Ventilation Design

Since man began using indoor fires for heating, ventilation of indoor air has existed, and still today the primary source of indoor air quality issues result from inadequate ventilation. Contemporary building contaminants, including VOC’s and synthetic fibers from building and furnishing materials; microbials, carbon dioxide, carbon monoxide, radon, asbestos, etc. can trigger discomfort, illness, allergic reactions, and temperature and humidity both impact concentrations of certain contaminants. In broad terms, ventilation design involves natural ventilation, mechanical ventilation, or local exhaust.

Well designed and maintained HVAC systems provide thermal comfort while using outdoor air to ventilate, dilute, isolate, and exhaust odors and contaminants. The ICC, through The International Building Code (IBC), by reference to ASHRAE 55-2010, Thermal Environmental Conditions for Human Occupancy and; 62.1-2010, Ventilation for Acceptable Indoor Air Quality dictates comfort (temperature, humidity, air movement) and ventilation parameters. Comfort and ventilation standards have significantly evolved since the very early part of the 20th century when the first standards for thermal comfort and ventilation became requirements, to reflect changing patterns in building space use, outdoor pollutants, complex variety of chemicals and components in building and furnishing materials, energy conservation goals, to name a few.

Building Standards will continue to transform especially in regards to ventilation, to resolve the seemingly disparate design goals for more ventilation and lower energy consumption. Particularly interesting developments for design integration of energy simulation and CFD (computational fluid dynamics) in the design process, and occupant-specific, dynamic systems, are promising.

FOR MORE INFORMATION: Bruce Bell, PE, Senior Technical Director, Mechanical and Plumbing Engineering

Part 3: Structural Alterations and Additions

The average building life cycle of non-residential structures extends many, many years. In fact, according to the US Energy Information Administration’s (EIA) 2012 report, Commercial Buildings Energy Consumption Survey, “commercial buildings remain in use for many decades. Although about 12% of commercial buildings (comprising 14% of commercial floorspace) were built since 2003, the commercial building stock is still fairly old, with about half of all buildings constructed before 1980; the median age of buildings in 2012 was 32 years.” It’s also true that within a short period of time, buildings become functionally unsuitable, or that facilities constructed for one product or purpose evolves to serve another.

So, distinct from normal operations and maintenance activities, continuous investment in research and development, production and logistics requires that alterations, additions, reuse, reallocation of space be permitted to comply with building safety standards, including structural codes. Like the applicable zoning, electrical, mechanical, plumbing codes, the structural codes are also updated to reflect new or better understood threats to building safety. For instance, it is important that new equipment installation for research or manufacturing tools be evaluated for foundation or floor structural capacity. Similarly, a comprehensive building structural analysis may be necessary with the installation of new overhead cranes or conveying equipment installation where there exists multiple generations of similar equipment; it’s not atypical to discover that over time and staff turnover, historical knowledge of the building changes are lost.

FOR MORE INFORMATION: Patrick McCoy, PE